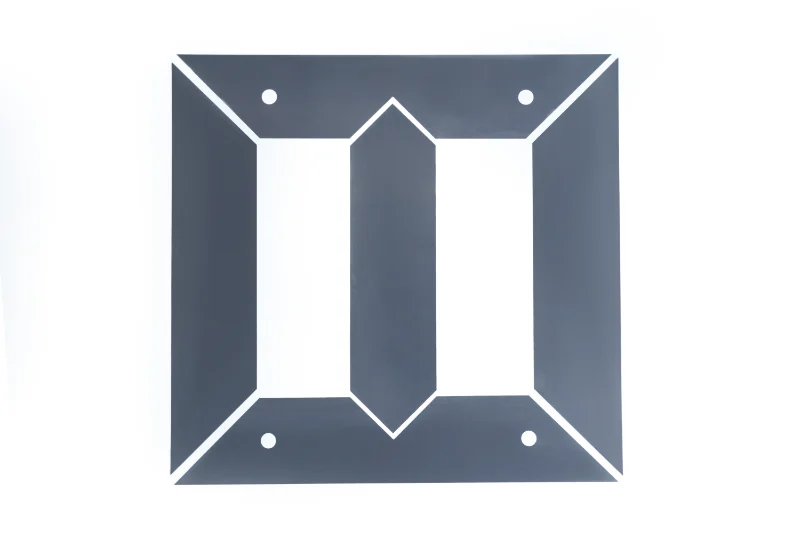

Plastics 3D Printing parts

3D printing is an additive manufacturing process where a three-dimensional object is crafted layer by layer, following a digital model.

3D printing is an additive manufacturing process where a three-dimensional object is crafted layer by layer, following a digital model.

No longer confined to prototyping or simple designs, modern 3D printers can produce complex geometries, employ a range of materials from plastics to metals, and are utilized in industries ranging from fashion to aerospace.

What are the Primary Advantages of 3D Printing?

✱Rapid Prototyping

✱Cost Efficiency

✱Design Flexibility

✱Sustainability

✱On-demand Production

✱Quality Assurance

Promotes Rapid Prototyping and Fast Design

The beauty of 3D printing lies in its transformative capability. When a company has an idea, 3D printing can swiftly convert this idea into a tangible prototype. Unlike traditional manufacturing methods that often involve extensive tooling and setup, 3D printers can produce a part as soon as the design is finalized. This speed is revolutionary in product development. Consider the following:

· Immediate Realization of Concepts: As soon as designers have a 3D model or CAD file, they can use the 3D printer to bring that design to life. It eliminates the prolonged waiting times of other manufacturing processes.

· Real-world Testing and Iterations: After printing and post processing, the part is ready for testing, and designers can adjust the model to incorporate any needed modifications and print again, allowing for rapid iterations based on real-world feedback.

· Customization on Demand: In the same vein, if a customer or client wants a slight tweak to a design, it can be done very quickly without altering the entire manufacturing process.

This approach speeds up product development and paves the way for innovations and ideas to come to life in record time.

Cost-Effective

While the initial investment in 3D printing equipment might be substantial, the long-term benefits and the return on investment (ROI) are profound. Additive manufacturing, the underlying principle of 3D printing, is a game-changer in cost management. Here’s why:

· Savings on Material Costs: The 3D printing process only adds material where needed. This method contrasts sharply with processes like CNC machining, injection molding, or other manufacturing technologies, which remove material, leading to potential waste. As such, there can be a marked reduction in material costs with 3D printing.

· Labor and Operational Efficiency: A traditional manufacturing process often requires skilled labor for various tasks, from operating machines to post-processing. In the world of 3D printing, a single operator can often oversee multiple 3D printers, translating to decreased labor costs.

· Reduced Inventory and Warehousing Costs: With 3D printing, businesses can print on demand. This capability reduces inventory costs, as companies no longer need vast warehouses to stock products. Moreover, as an added bonus, it also reduces transport costs, as goods can be produced closer to the point of sale.

The advantages of 3D printing in streamlining the supply chain, optimizing the production process, and ultimately improving a business’s bottom line are clear.

3D Printing Offers More Design Freedom

One of the most lauded advantages of 3D printing is its unparalleled freedom for designers. Traditional manufacturing techniques often place constraints on what can be produced. With 3D printing, these boundaries are pushed, if not entirely erased.

· Complex Geometries and Lattices: Intricate designs, which would have been nearly impossible or prohibitively expensive with conventional manufacturing methods, are now feasible. For instance, aerospace and automotive industries can create components with complex lattices without compromising strength.

· Internal Cavities and Voids: The 3D printing process can create objects with internal cavities and voids, essential for specific applications, especially in medical care, such as implants or prostheses.

· Customization and Personalization: The term ‘mass customization’ truly comes to life with 3D printing. The possibilities are vast, whether personalized consumer goods or tailored medical devices suited to an individual’s anatomy.

· Integration of Parts: Traditional manufacturing often involves producing individual components, which are later assembled. 3D printing can produce assemblies as a single part, reducing assembly time and potential errors.

Reviews

There are no reviews yet.