Precision Casting Machining

✔ High Precision – Tolerances as tight as ±0.005 in (±0.127 mm). ✔ Excellent Surface Finish – Typically 125–250 µin (3.2–6.3 μm Ra) without machining.

Precision casting machining represents the pinnacle of modern manufacturing technology, combining the intricacy of investment casting with the accuracy of advanced machining processes. This technique is employed to create highly complex and high-precision components that are essential in various industries. At Vibo Precision, we specialize in delivering top-tier precision casting machining solutions that meet the most stringent requirements.

Advantages of Precision Casting Machining

1. Exceptional Precision

Our precision casting machining process achieves tolerances as tight as ±0.005 in (±0.127 mm). This level of precision ensures that each component meets the exact specifications required for critical applications, reducing the need for extensive post-processing and minimizing the risk of component failure.

2. Superior Surface Finish

The surface finish of our precision castings is typically 125–250 µin (3.2–6.3 μm Ra) without the need for additional machining. This smooth finish not only enhances the aesthetic appeal of the parts but also improves their functionality, especially in applications where surface roughness can affect performance.

3. Complex Geometries

With precision casting machining, we can produce components with intricate details, thin walls, and internal passages. This capability allows for the creation of lightweight yet robust parts that would be impossible or cost-prohibitive to manufacture using traditional methods.

4. Wide Material Compatibility

Our process supports a wide range of materials, including stainless steel (304, 316, 17-4PH), aluminum alloys (A356, 6061, 7075), titanium alloys (Ti-6Al-4V), superalloys (Inconel, Hastelloy), and carbon & low-alloy steels. This versatility ensures that we can meet the specific material requirements of various industries.

5. Cost-Effective Solutions

While precision casting machining is known for its high precision, it also offers cost-effective solutions. By reducing the need for extensive post-processing and minimizing material waste, our process helps lower overall production costs without compromising on quality.

Features of Precision Casting Machining

1. Customization

We offer fully customized solutions tailored to your specific needs. From initial design consultations to final product delivery, our team works closely with you to ensure that every aspect of the casting and machining process meets your requirements.

2. Consistency and Reliability

Our state-of-the-art machinery and stringent quality control measures ensure that each component is produced with the same level of precision and quality. This consistency is crucial for industries that rely on high-performance parts with zero tolerance for defects.

3. Rapid Prototyping

Utilizing advanced 3D printing technology for pattern creation, we can quickly produce prototypes for testing and validation. This accelerates the product development cycle and allows for timely adjustments based on feedback.

4. Post-Processing Services

In addition to precision casting, we offer a range of post-processing services, including grinding, machining, heat treatment, and surface finishing. These services ensure that your components are ready for immediate use upon delivery.

Precision Casting Machining Process

1. Pattern Creation

The process begins with the creation of a wax or polymer pattern using injection molding or 3D printing. These patterns are designed to match the exact specifications of the final component. Multiple patterns can be assembled into a wax tree to cast multiple parts simultaneously.

2. Shell Building (Investment)

The wax pattern is dipped into a ceramic slurry and coated with fine refractory sand. This process is repeated several times to build a thick, heat-resistant ceramic shell. The shell is then dried and hardened to ensure its structural integrity.

3. Dewaxing

The ceramic-coated wax assembly is heated in an autoclave or furnace, melting out the wax. The remaining hollow ceramic mold is fired at high temperatures to strengthen it before metal pouring.

4. Metal Casting

Molten metal, such as stainless steel, aluminum, or titanium, is poured into the preheated ceramic mold. The metal solidifies inside the mold, taking the exact shape of the original wax pattern.

5. Shell Removal & Finishing

After cooling, the ceramic shell is broken away using vibration or water blasting. Individual castings are cut from the tree, and post-processing services are applied to achieve the desired finish and tolerances.

Applications of Precision Casting Machining

1. Aerospace & Defense

Precision casting machining is ideal for manufacturing turbine blades, engine components, and missile parts. These components require high precision, strength, and reliability to withstand extreme conditions.

2. Medical & Dental

In the medical and dental industries, precision casting is used to produce surgical instruments and orthopedic implants. The high precision and biocompatibility of the materials ensure the safety and effectiveness of these critical components.

3. Automotive

For the automotive industry, precision casting machining is used to create turbocharger housings and transmission parts. These components benefit from the lightweight and high-strength characteristics of precision castings, contributing to improved fuel efficiency and performance.

4. Industrial & Energy

In industrial and energy applications, precision casting machining is used to produce pump housings, valve bodies, and hydraulic components. These parts require high precision and durability to operate efficiently in demanding environments.

Comparison with Other Casting Methods

|

Feature |

Investment Casting |

Sand Casting |

Die Casting |

|

Tolerance |

±0.005 in |

±0.030 in |

±0.002 in |

|

Surface Finish |

Very Smooth |

Rough |

Smooth |

|

Complexity |

Very High |

Moderate |

High |

|

Cost |

Medium-High |

Low |

Medium |

|

Best For |

High-precision parts |

Large, simple parts |

High-volume aluminum/zinc parts |

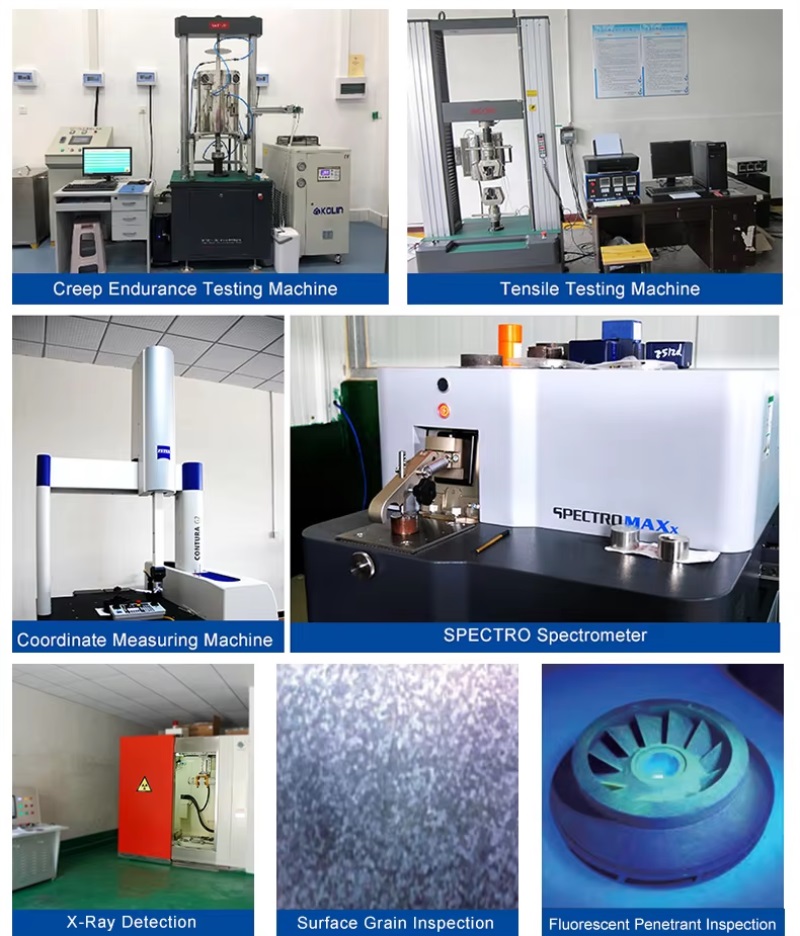

Quality Inspection

Packaging and Shipping

FAQs

1. What materials can be used in precision casting machining?

We support a wide range of materials, including stainless steel, aluminum alloys, titanium alloys, superalloys, and carbon & low-alloy steels. The choice of material depends on the specific requirements of the application.

2. How long does the precision casting machining process take?

The duration of the process depends on the complexity of the part and the quantity required. Typically, the process from pattern creation to final product can take anywhere from a few days to several weeks. Rapid prototyping can significantly reduce this time.

3. Can precision casting machining be used for large-scale production?

Yes, precision casting machining is suitable for both small-batch prototyping and large-scale production. Our advanced technology and efficient processes ensure consistent quality regardless of the production volume.

4. What industries benefit the most from precision casting machining?

Industries that require high-precision, lightweight, and corrosion-resistant parts benefit the most from precision casting machining. This includes aerospace, defense, medical, automotive, and industrial sectors.

5. How do I get a quote for precision casting machining services?

To get a quote, simply contact us with your specific requirements, including part specifications, material preferences, and quantity. Our team will provide a detailed quote based on your needs.

At Vibo Precision, we are committed to delivering the highest quality precision casting machining services. Our expertise, advanced technology, and dedication to customer satisfaction ensure that your components meet the most stringent standards. Contact us today to discuss your precision casting needs and discover how we can help bring your vision to life.

Reviews

There are no reviews yet.